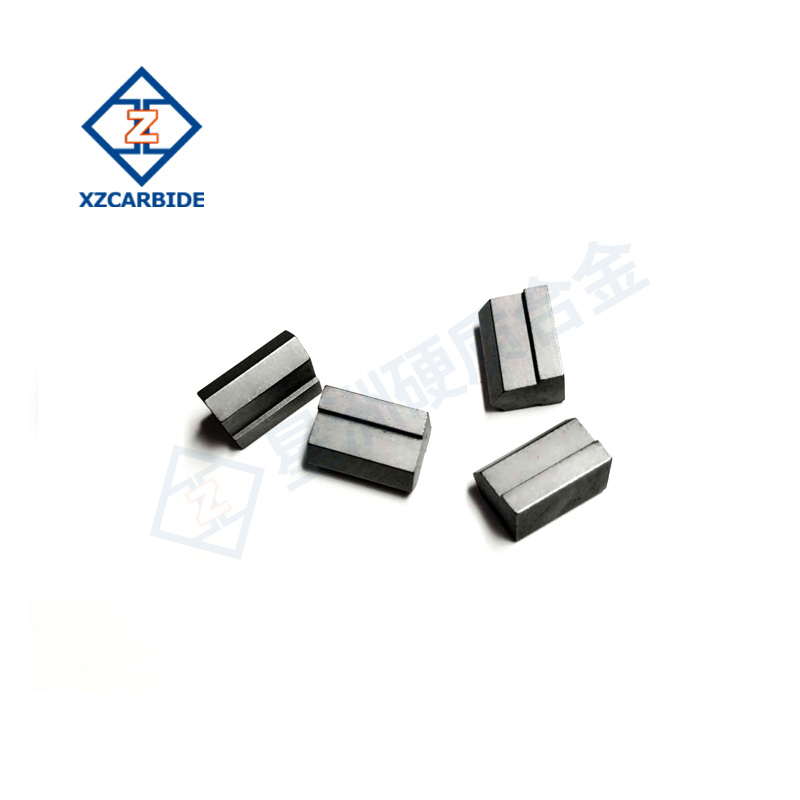

Product Features

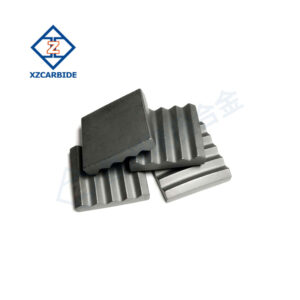

- Excellent wear resistance: High hardness tungsten carbide material is used to ensure that the brazing inserts are used for a long time under high load conditions and reduce wear.

- Outstanding high temperature resistance: Brazing inserts maintain stable performance in high-temperature processing environments, prolonging service life.

- High strength: Brazing process makes the brazing inserts tightly bonded with the cutter body, providing higher impact resistance and suitable for high-intensity cutting tasks.

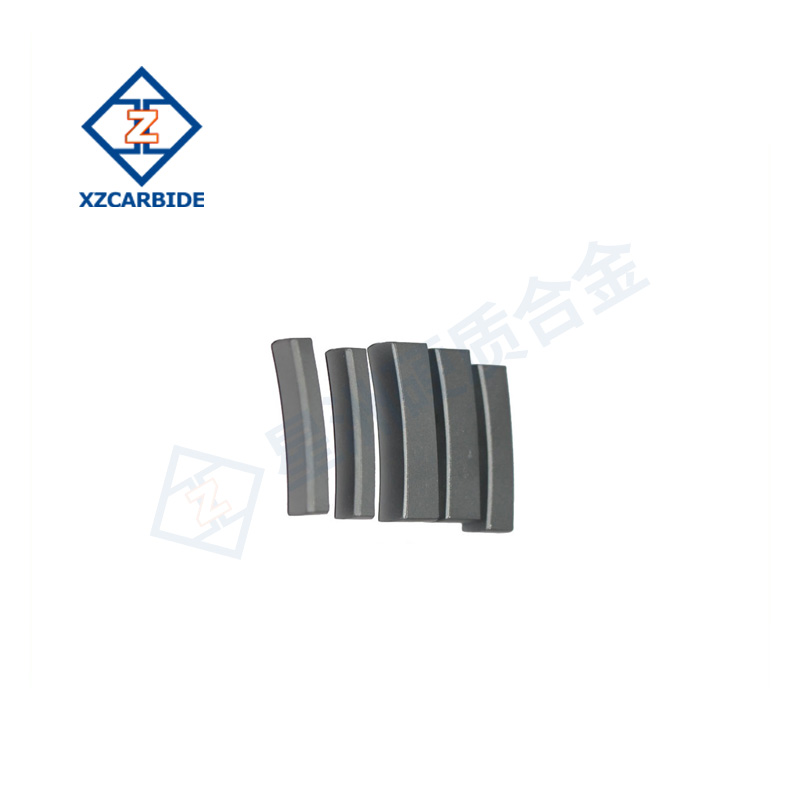

- Efficient cutting ability: Designed for ore and rock drilling and crushing, it provides efficient and fast cutting experience to enhance the efficiency of mining operations.

- Versatile application: Suitable for cutting various materials, such as steel, cast iron, stainless steel and other difficult-to-machine materials.

Applications

Used in drill bits for drilling tools, inserts for milling tools, rock drilling equipment for mining tools, etc.

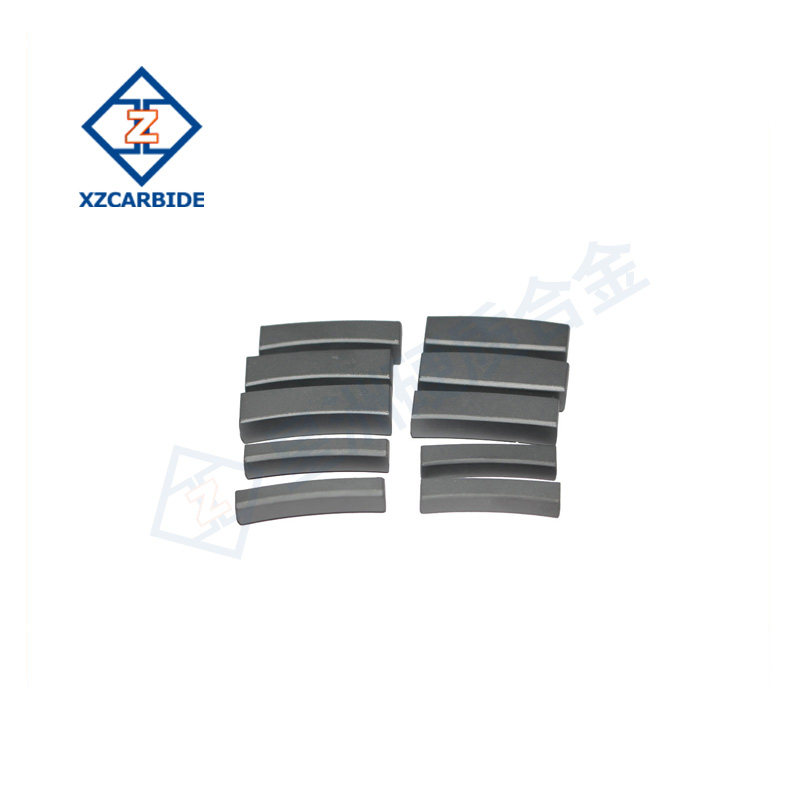

- Ore drilling: Suitable for all kinds of ore drilling bits, which can easily deal with hard minerals and ensure efficient drilling.

- Rock crushing: Applicable to rock crushing equipment, providing long and stable cutting performance and reducing downtime.

- Mining equipment accessories: Widely used in mining machinery tooling accessories to enhance the overall durability and productivity of the equipment.

Reviews

There are no reviews yet.