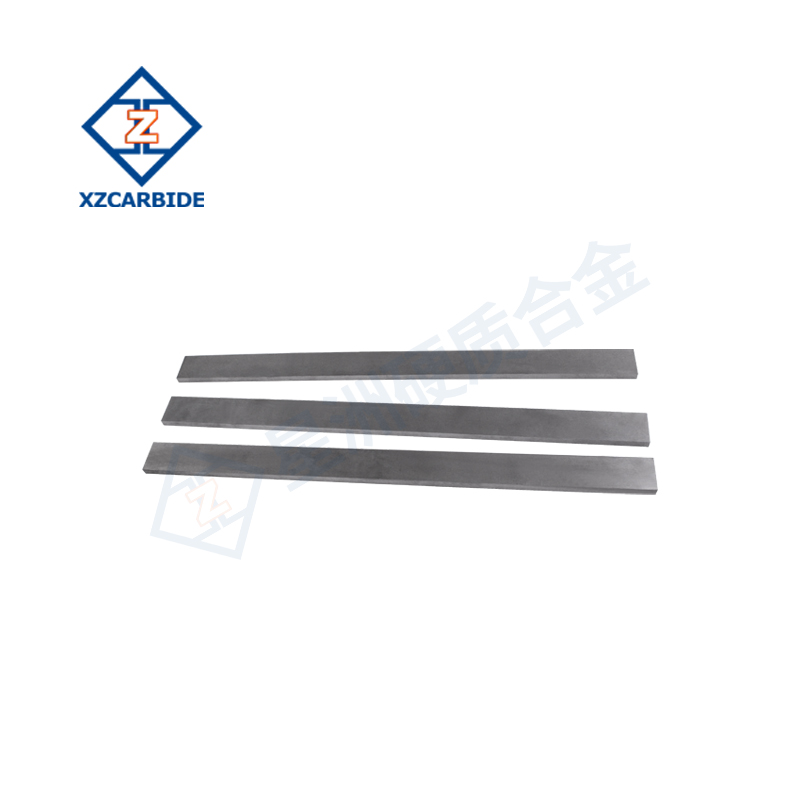

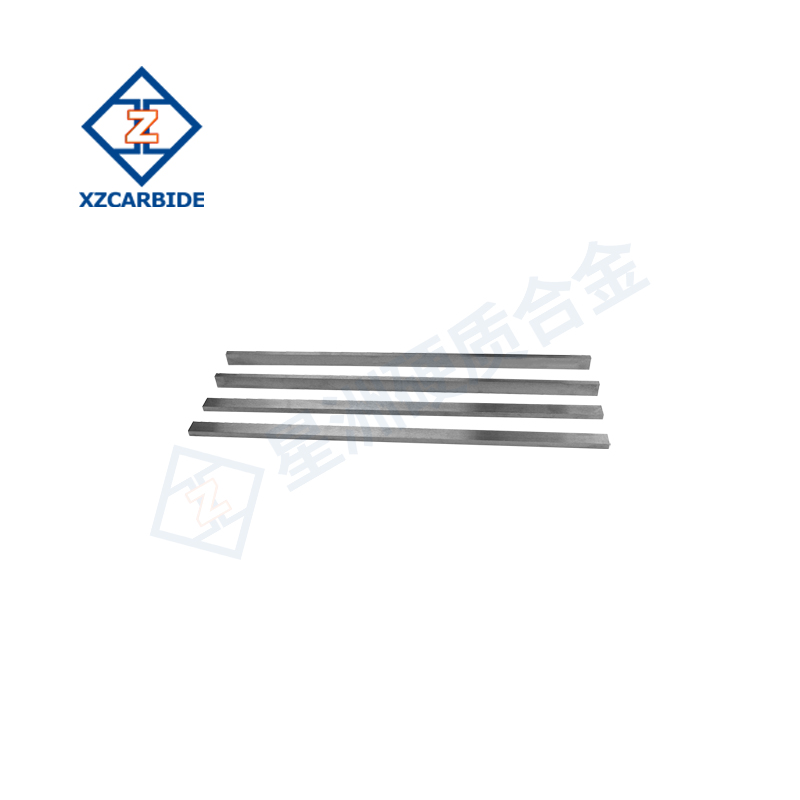

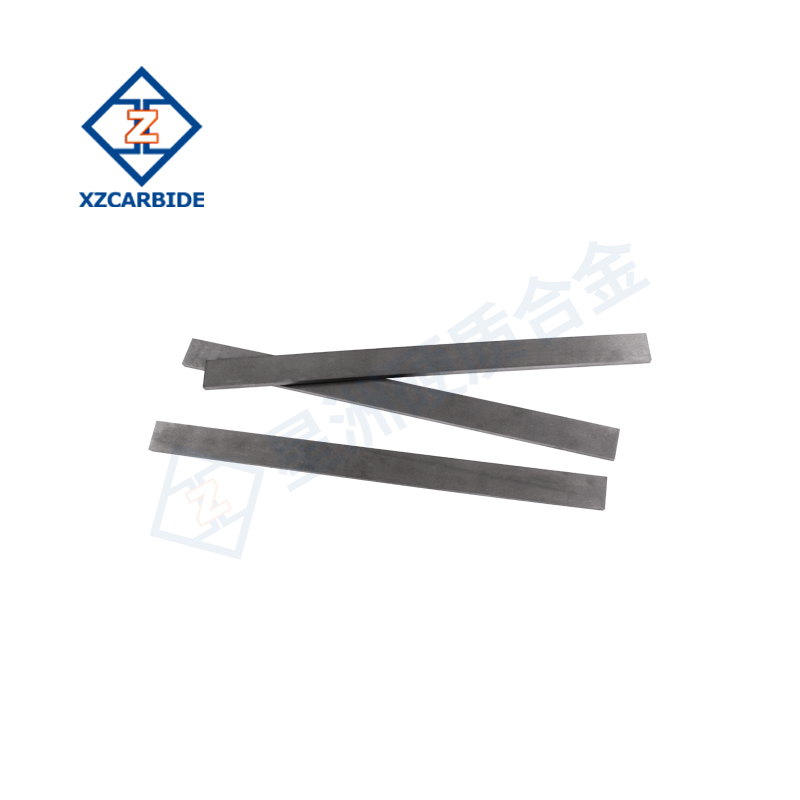

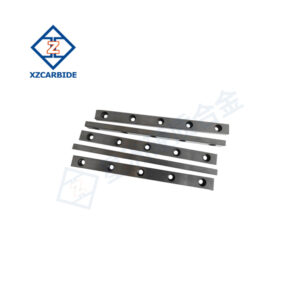

Specifications of Cemented Carbide Strips

| Dimensions (T*WxL, mm) | Thickness Tolerance (mm) | Width Tolerance (mm) | Length Tolerance (mm) |

| 1x(2~5)x length | Thickness = 7.0 Tolerance: +0.2/+ 0.5;Thickness > 7 Tolerance: +0.2/+0.7 | Width = 30 Tolerance: + 0.2/+0.6Width > 30 Tolerance: +0.2/+0.8 | Length < 100 Tolerance: 0/+ 1.0;100 ≤ Length < 200 Tolerance: 0/+2.0;Length = 200 Tolerance: 0/+5.0 |

| 1.5x(2~10)xlength | |||

| 2.0x(3.5~15)xlength | |||

| 2.5x(2.5~20)x length | |||

| 3.0x(3.0~20)xlength | |||

| 3.5x(3.5~25)xlength | |||

| 4.0x(4.030)xLength | |||

| 5.0x(4.0~40)xlength | |||

| 6.0x(5.0~40)xlength | |||

| (7~20) x(7~40) x length |

Product Features

- Extremely high hardness, able to resist strong abrasion and cutting forces, ensuring that the tools remain sharp under prolonged use.

- Good strength and toughness, can withstand large impact and bending force without breaking.

- Excellent resistance to a wide range of chemicals, not easy to be corroded or oxidized.

- Stable performance under high temperature environment, it is not easy to be deformed or fail.

- Available to customize tungsten carbide bars of different sizes, shapes and specifications according to customers’ needs.

Application Areas

- Cutting tools: Used in the manufacture of drills, milling cutters, planer cutters and other cutting tools.

- Mould manufacturing: Used to make wear-resistant parts for cold punching molds, injection molds and other molds.

- Wear-resistant parts: Used for manufacturing wear-resistant parts of various machines.

Reviews

There are no reviews yet.